Contact Us

Mr.Yang:+86 15801686799

E-mail:yang@rssteelpipe.com

Add:Puwacheng Industrial Park, Yanshan Economic Development Zone

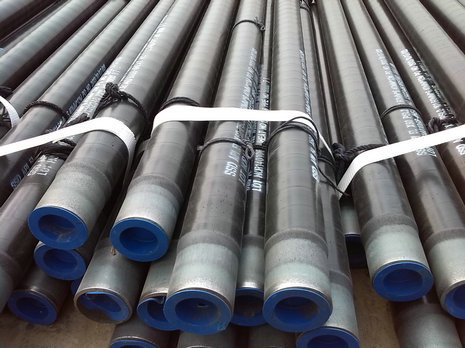

Inner and outer plastic-coated composite steel pipe

Plastic-coated composite steel pipe, also known as plastic-coated steel pipe, is a steel-plastic composite product with steel pipe as the base pipe and plastic powder as the coating material. A plastic layer is melted and coated on its inner surface, and a plastic layer or other material anti-corrosion layer is coated on its outer surface.

Key words:

Inner and outer plastic-coated composite steel pipe

Classification:

Description

Plastic-coated composite steel pipe, also known as plastic-coated steel pipe, is a steel-plastic composite product with steel pipe as the base pipe and plastic powder as the coating material. A plastic layer is melted and coated on its inner surface, and a plastic layer or other material anti-corrosion layer is coated on its outer surface.

Coated composite steel pipes are classified into: hot-dip plastic coating process, internal and external spraying process, rotational molding process, dip coating process, suction coating process, fusion winding process, etc.

Hot-dip plastic coating adopts: fluidized bed plastic coating, one-time film formation method. Also known as the first-generation anti-corrosion of plastic-coated steel pipe, it is made of polyethylene both inside and out.

Internal and external spraying process: Based on the electrostatic adsorption theory, through the pretreatment of steel pipes, polyethylene or epoxy resin powder is sprayed with a spray gun. Also known as the second-generation anti-corrosion coated steel pipe, it is an inner and outer epoxy composite steel pipe.

Coating process: Also known as the curtain method, it is applied to the outer wall of the heated steel pipe by coating through a sieve filled with powder. As shown in the figure:

This process can produce outer polyethylene and inner epoxy composite steel pipes. Also known as the third-generation anti-corrosion of plastic-coated steel pipes.

Fusion-bonded winding process: The hot fusion-bonded winding method is adopted. Hot melt adhesive and polyethylene are wound around the heated steel pipe in the form of an extruder, and a reaction occurs to form a three-layer structure. The full name is fusion-bonded epoxy/extruded polyethylene structural protective layer. As shown in the figure:

This process can produce polyethylene composite steel pipes with an outer three-layer structure and an inner fusion-bonded epoxy structure. Also known as the fourth-generation anti-corrosion of plastic-coated steel pipes.

Inquiry