Contact Us

Mr.Yang:+86 15801686799

E-mail:yang@rssteelpipe.com

Add:Puwacheng Industrial Park, Yanshan Economic Development Zone

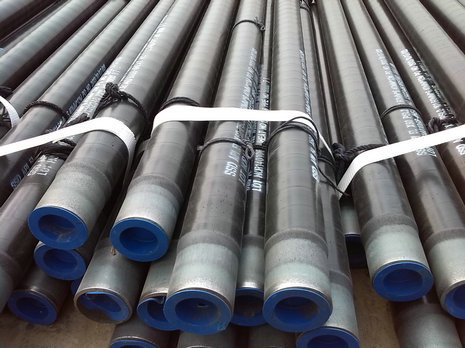

IPN8710 anti-corrosion steel pipe

Especially in those extremely dark and damp places with a lot of corrosive substances, the use of this kind of steel pipe is even more necessary.

Key words:

IPN8710 anti-corrosion steel pipe

Classification:

Description

The advantages of using IPN8710 anti-corrosion steel pipes

Especially in those extremely dark and damp places with a lot of corrosive substances, the use of this kind of steel pipe is even more necessary. Like sewers, where sewage, various garbage and so on are relatively hidden places and hard to detect. When steel pipes break or get damaged, the repair difficulty is also very high. Therefore, using this kind of steel pipe can extend the service life and has a stronger anti-corrosion function. IPN8710 anti-corrosion steel pipes have really brought a lot of convenience to people. Maybe some people would think that if they are corroded, they can just replace it with a new one. Of course, buying a new steel pipe is not difficult, but the process of replacement is really troublesome. Therefore, IPN8710 anti-corrosion steel pipes are steel pipes that save people time, effort and convenience.

Comprehensive performance of IPN8710 anti-corrosion steel pipe:

1. Simple surface treatment;

2. Excellent anti-corrosion performance;

3. The performance-to-price ratio is reasonable.

According to the thickness of the steel pipe, the specified film thickness of the coating and the requirements of the epoxy zinc-rich primer, the steel pipe body must undergo mechanical rust removal treatment (shot blasting or sandblasting), and the surface cleanliness and roughness of the steel should meet the following indicators:

1. Cleanliness: Reaching the sa2.5 grade of GB8923-1988, which is defined as: extremely thorough jet cleaning. When observed without magnification, the surface should be free of visible grease and dirt, as well as oxide scale, rust, old coatings and foreign substances, leaving only slight traces in the form of dots or stripes.

2. Roughness: Also known as the surface profile of steel space, it is the height of the surface profile measured from the lowest point of the valley to the highest point of the peak, and it is a safety technical index of the surface treatment grade. In the sy/ T0447-96 standard, there are relevant roughness requirements for epoxy asphalt paint. The surface roughness of the steel pipe should be controlled within 70 to 90μm, which belongs to the medium level of sandy abrasives or the primary level of shot abrasives as stipulated in the gb/t13288 standard.

Anti-corrosion coating for IPN8710 anti-corrosion steel pipes

IPN8710 anti-corrosion steel pipe is a two-component coating. The base material of Component A: resin, initiator. Group B base material: active monomer, catalyst. When Group A and Group B are mixed in equal amounts, the three networks interpenetrate at the molecular level, forming an interpenetrating polymer network (IPN) structure and generating a synergistic effect. The network formed by this coating has the following characteristics: strong adhesion, good flexibility, and resistance to corrosive media such as acids, alkalis, and salts. It further enhances the toughness, strength, adhesion, impermeability and chemical inertness of the coating, endowing the coating film with better performance. By forming IPN to improve the performance of polymers, it is a new type of polymer blending technology.

Inquiry