Contact Us

Mr.Yang:+86 15801686799

E-mail:yang@rssteelpipe.com

Add:Puwacheng Industrial Park, Yanshan Economic Development Zone

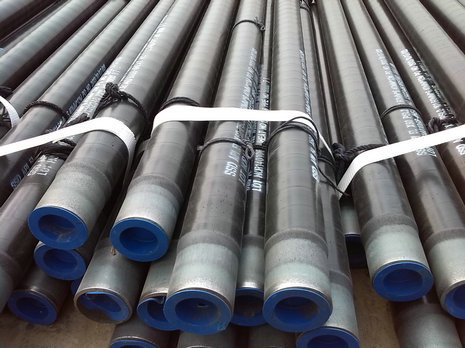

Spiral steel pipe

Spiral steel pipes are made from steel strip coils as raw materials, formed by extrusion at room temperature, and welded by automatic double-wire double-sided submerged arc welding process to form spiral seam steel pipes.

Key words:

Spiral steel pipe

Classification:

Description

Spiral steel pipes are made from steel strip coils as raw materials, formed by extrusion at room temperature, and welded by automatic double-wire double-sided submerged arc welding process to form spiral seam steel pipes. The spiral steel pipe sends the steel strip into the welded pipe production line. After being rolled by multiple rolls, the steel strip gradually rolls up to form a circular tube blank with an open gap. By adjusting the reduction of the extrusion rolls, the weld gap is controlled within 1 to 3mm, and both ends of the weld are made flush.

Production process

The raw materials are steel strip coils, welding wires and fluxes. All must undergo strict physical and chemical tests before being put into use.

(2) The head and tail of the steel strip are joined by single wire or double wire submerged arc welding. After being rolled into steel pipes, automatic submerged arc welding is used for repair welding.

(3) Before forming, the steel strip undergoes leveling, trimming, planing, surface cleaning and conveying, as well as pre-bending edge treatment.

(4) The pressure of the oil cylinders on both sides of the conveyor is controlled by an electrical contact pressure gauge, ensuring the smooth transportation of the steel strip.

(5) Adopt external control or internal control roller forming.

(6) A weld gap control device is adopted to ensure that the weld gap meets the welding requirements, and the pipe diameter, misalignment and weld gap are all strictly controlled.

(7) Both the inner and outer welding are carried out by using Lincoln welding machines from the United States for single wire or double wire submerged arc welding, thus achieving stable welding quality.

(8) All the weld seams after welding are inspected by an online continuous ultrasonic automatic non-destructive testing instrument, ensuring a 100% non-destructive testing coverage rate for spiral weld seams. If there are any defects, an automatic alarm will be triggered and marks will be sprayed. Production workers can adjust the process parameters at any time based on this to eliminate the defects promptly.

(9) Use an air plasma cutting machine to cut the steel pipes into single pieces.

(10) After being cut into individual steel pipes, each batch of steel pipes must undergo a strict first inspection system to check the mechanical properties, chemical composition, fusion status of the (11) weld seams, surface quality of the steel pipes, and pass non-destructive testing. Only after ensuring that the pipe-making process is qualified can they be officially put into production.

For the parts of the weld seam with continuous ultrasonic flaw detection marks, manual ultrasonic and X-ray rechecks are conducted. If there are indeed defects, after repair, non-destructive testing is carried out again until it is confirmed that the defects have been eliminated.

(12) All pipes where the butt welds of the steel strip and the T-joints intersecting with the spiral welds are located shall be inspected by X-ray television or radiography.

(13) Each steel pipe undergoes a hydrostatic test, and the pressure is sealed radially. The test pressure and time are strictly controlled by the microcomputer water pressure detection device for steel pipes. The test parameters are automatically printed and recorded.

(14) The mechanical processing of the pipe ends ensures that the verticality of the end face, the bevel Angle and the dull edge are accurately controlled.

Weld seam treatment

1.If the gap is too large, it will lead to a reduction in the proximity effect, insufficient eddy current heat, and poor intergranular bonding of the weld seam, resulting in incomplete fusion or cracking.

2. If the gap is too small, the proximity effect will increase, the welding heat will be excessive, and the weld seam will be burned out. Or the weld seam forms a deep pit after being extruded or rolled, which affects the surface quality of the weld seam.

After heating the two edges of the tube blank to the welding temperature, under the extrusion of the extrusion roller, common metal grains interpenetrate and crystallize, eventually forming a firm weld seam. If the squeezing force on the spiral steel pipe is too small, the number of common crystals formed will be small, the strength of the weld metal will decrease, and cracking will occur after being subjected to force. If the extrusion force is too large, the molten metal will be squeezed out of the weld seam, not only reducing the strength of the weld seam, but also generating a large number of internal and external burrs, and even causing defects such as welding lap joints.

Inquiry