Contact Us

Mr.Yang:+86 15801686799

E-mail:yang@rssteelpipe.com

Add:Puwacheng Industrial Park, Yanshan Economic Development Zone

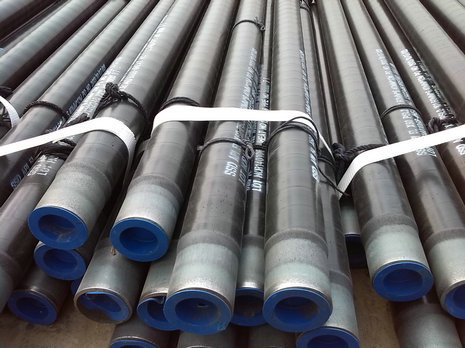

Seamless steel pipe

A steel pipe made of a single piece of metal without any seams on its surface is called a seamless steel pipe. According to the production method, seamless pipes are classified into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, extruded pipes, and jacking pipes, etc.

Key words:

Seamless steel pipe

Classification:

Description

A steel pipe made of a single piece of metal without any seams on its surface is called a seamless steel pipe. According to the production method, seamless pipes are classified into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, extruded pipes, and jacking pipes, etc. According to the cross-sectional shape, seamless steel pipes are divided into two types: round and special-shaped. Special-shaped pipes come in various complex shapes such as square, oval, triangular, hexagonal, melon seed-shaped, star-shaped, and finned pipes. The maximum diameter reaches 650mm and the minimum diameter is 0.3mm. Depending on the use, there are thick wall and thin wall tube. Seamless steel pipes are mainly used as oil and gas geological drilling pipes, cracking pipes for petrochemicals, boiler pipes, bearing pipes, as well as high-precision structural steel pipes for automobiles, tractors and aviation.

Production process

① Main production processes of hot-rolled seamless steel pipes (△ Main inspection processes) :

Tube blank preparation and inspection △→ Tube blank heating → Piercing → Pipe rolling → Reheating of steel pipe → sizing (reducing) → Heat treatment △→ Straightening of finished pipe → finishing → inspection △ (non-destructive, physical and chemical, bench inspection) → storage

② Main production processes of cold-rolled (drawn) seamless steel pipes:

Billet preparation → pickling and lubrication → cold rolling (drawing) → heat treatment → Straightening → finishing → inspection

The production processes of general seamless steel pipes can be divided into cold drawing and hot rolling. The production process of cold-rolled seamless steel pipes is generally more complex than that of hot-rolled ones. The pipe billets first undergo three-roll continuous rolling, and after extrusion, they need to undergo sizing tests. If there are no corresponding cracks on the surface, the round pipes need to be cut by a cutting machine to cut billets about one meter in length. Then the annealing process begins. During annealing, acidic liquid is used for pickling. During pickling, it is necessary to pay attention to whether there are a large number of bubbles on the surface. If there are a large number of bubbles, it indicates that the quality of the steel pipe does not meet the corresponding standards. In terms of appearance, cold-rolled seamless steel pipes are shorter than hot-rolled seamless steel pipes. The wall thickness of cold-rolled seamless steel pipes is generally smaller than that of hot-rolled seamless steel pipes, but the surface looks brighter than thick-walled seamless steel pipes, with less roughness on the surface and fewer burrs on the diameter.

The delivery state of hot-rolled seamless steel pipes is generally delivered after heat treatment in the hot-rolled state. After quality inspection, hot-rolled seamless steel pipes must go through strict manual selection by staff. After quality inspection, surface oiling is carried out, followed by multiple cold drawing tests. After hot rolling treatment, a piercing test is conducted. If the piercing expansion is too large, straightening correction is required. After straightening, it is conveyed to the flaw detector by the conveying device for flaw detection tests. Finally, it is labeled, arranged in specifications and placed in the warehouse.

Round tube billet → heating → piercing → three-roll cross-rolling, continuous rolling or extrusion → de-tubing → sizing (or reducing) → cooling → straightening → hydrostatic test (or flaw detection) → marking → storage. Seamless steel pipes are made from steel ingots or solid tube billets through piercing to form rough tubes, and then processed by hot rolling, cold rolling or cold drawing. The specifications of seamless steel pipes are indicated by the outer diameter multiplied by the wall thickness in millimeters.

The outer diameter of hot-rolled seamless tubes is generally greater than 32mm, and the wall thickness is 2.5-200mm. The outer diameter of cold-rolled seamless steel tubes can reach 6mm, and the wall thickness can reach 0.25mm. The outer diameter of thin-walled tubes can reach 5mm, and the wall thickness is less than 0.25mm. Cold-rolled tubes have higher dimensional accuracy than hot-rolled ones.

Generally, seamless steel pipes are made by hot rolling or cold rolling of high-quality carbon structural steels such as 10, 20, 30, 35, and 45, low alloy structural steels such as 16Mn and 5MnV, or composite structural steels such as 40Cr, 30CrMnSi, 45Mn2, and 40MnB. Seamless pipes made of low-carbon steel such as 10 and 20 are mainly used for fluid conveying pipelines. Seamless tubes made of medium carbon steel such as 45 and 40Cr are used to manufacture mechanical parts, such as the load-bearing parts of automobiles and tractors. Generally, for seamless steel pipes, it is necessary to ensure strength and flatness tests. Hot-rolled steel pipes are delivered in either hot-rolled or heat-treated condition. Cold-rolled products are delivered in heat-treated condition.

Inquiry