Contact Us

Mr.Yang:+86 15801686799

E-mail:yang@rssteelpipe.com

Add:Puwacheng Industrial Park, Yanshan Economic Development Zone

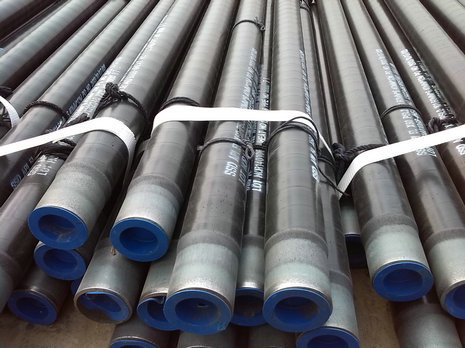

3PE Anti-Corrosion Steel Pipe

The base materials of 3PE anti-corrosion steel pipes include seamless steel pipes, spiral steel pipes and straight seam steel pipes. The three-layer polyethylene (3PE) anti-corrosion coating has been widely used in the petroleum pipeline industry due to its excellent corrosion resistance, water vapor permeability resistance and mechanical properties.

Key words:

3PE Anti-Corrosion Steel Pipe

Classification:

Description

The anti-corrosion coating of 3PE anti-corrosion steel pipes is crucial to the lifespan of buried pipelines. Pipes of the same material may not corrode for decades when buried underground, while others may leak within just a few years. It is precisely because they adopt different external anti-corrosion coatings.

3PE anti-corrosion is generally composed of three layers:

The first layer of epoxy powder (FBE>100um)

The second layer of adhesive (AD) is 170-250 μ m

The third layer of polyethylene (PE) is 2.5 to 3.7mm

In actual operation, the three materials are mixed and integrated, and after processing, they are firmly combined with the steel pipe to form an excellent anti-corrosion layer. Its processing methods are generally divided into two types: winding type and circular die covering type.

The advantages of the anti-corrosion layer of 3PE anti-corrosion steel pipes

The coating of 3PE anti-corrosion steel pipes is that the bottom layer in contact with the surface of the steel pipe is an epoxy powder anti-corrosion coating, and the middle layer is a copolymer adhesive with branched structural functional groups. The surface layer is a high-density polyethylene anti-corrosion coating. The 3PE anti-corrosion steel pipe coating, also known as the three-layer polyethylene anti-corrosion coating, is a new type of anti-corrosion steel pipe coating that ingeniously combines the 2PE anti-corrosion layer from Europe with the epoxy powder anti-corrosion steel pipe coating (FBE) widely used in North America. It has been recognized and used worldwide for more than ten years.

Inspection process for 3PE anti-corrosion steel pipes

First, inspect the anti-corrosion steel pipes. Based on various conditions, conduct a comprehensive inspection of the steel pipes to ensure they meet the requirements for manufacturing insulated steel pipes. Check whether the steel pipes have been corroded and inspect and remove the rust on the steel pipes. The next step is to place the rust-removed and anti-corrosion treated steel pipe inside the polyethylene sleeve for pipe threading and forming. However, after the head is repaired, polyurethane foam is injected inside to fully fill the gaps and ensure thorough filling. Inspect the anti-corrosion steel pipes and conduct finished product inspection on the completed insulated steel pipes.

Before the 3PE anti-corrosion steel pipe base material is subjected to anti-corrosion treatment, it is necessary to inspect and record the steel pipes entering the pipe feeding platform. The outer surface of the steel pipes should be shot blasted for rust removal. Then, the cleanliness of the outer surface of the steel pipes and the depth of the anchor pattern should be checked to see if they meet the requirements. If they do not meet the requirements, they should be ground and repaired with a hand grinding wheel to be qualified. Wrap adhesive tape paper around the pipe end, perform dust removal treatment, and heat at medium frequency to the required temperature. Cyclic oxygen powder is sprayed and coated, adhesive is wound on the side of the extruder, PE is wound and burned on the side of the extruder, water cooling is carried out on the anti-corrosion pipe, qualified products are sprayed and marked, and the pipe is placed on the pipe platform and stacked for shipment.

Inquiry