Contact Us

Mr.Yang:+86 15801686799

E-mail:yang@rssteelpipe.com

Add:Puwacheng Industrial Park, Yanshan Economic Development Zone

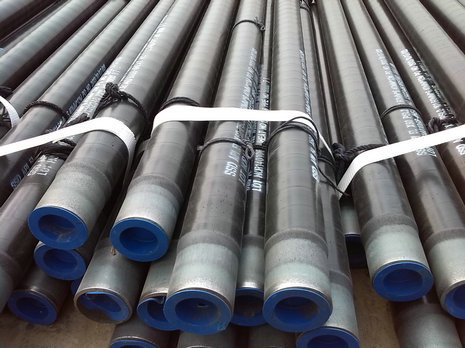

TPEP anti-corrosion steel pipe

TPEP anti-corrosion steel pipe - Outer 3PE inner fusible epoxy anti-corrosion steel pipe is an upgraded product based on the outer single-layer polyethylene inner epoxy composite steel pipe.

Key words:

TPEP anti-corrosion steel pipe

Classification:

Description

TPEP anti-corrosion steel pipe - Outer 3PE inner fusible epoxy anti-corrosion steel pipe is an upgraded product based on the outer single-layer polyethylene inner epoxy composite steel pipe. It is currently the most advanced form of steel pipe anti-corrosion for buried long-distance pipelines. It is the fourth-generation new anti-corrosion production line for large-diameter pipes independently developed by Youcheng Pipe Industry. The outer wall adopts a three-layer anti-corrosion layer structure composed of the bottom layer of epoxy resin, the middle layer of adhesive, and the outer layer of polyethylene through a hot-melt bonding process. The inner wall uses a hot-spray epoxy powder anti-corrosion method.

After the powder is heated at high temperature and fused, it is evenly coated on the surface of the pipe body to form a steel-plastic alloy layer. Abbreviated as TPEP steel pipe, (T is the first letter of the English word "Three", PE stands for polyethylene, and EP stands for epoxy resin). It greatly enhances the adhesion and thickness of the coating, and strengthens its resistance to impact and corrosion. This product was granted a national utility model patent in 2009. It was awarded the National Torch Program in 2010. TPEP steel pipes have filled the gap of the best anti-corrosion steel pipes in China. Their price is almost the same as that of single-layer polyethylene inner fusion-bonded epoxy composite steel pipes, and their corrosion resistance has increased by 3 to 5 times.

Technical parameters:

Product specifications: DN100-DN1800

Steel pipe material: Q235 or Q345

Coating materials: high-density polyethylene, food-grade epoxy powder

Universal colors: Black for the outer wall and gray for the inner wall

Coating thickness: 2.0-4.0mm for outer wall and 0.35-0.5mm for inner wall

Coating method: Fusion winding and thermal spraying are carried out simultaneously to form a film in one go.

Product length: 12 meters, or as specified

Conventional pressure: 0.1Mpa - 5.0Mpa

Connection method: Welding

Patching method: Inner lining with stainless steel and no need for repair technology

Application fields: long-distance water transmission pipelines, water conservancy industry, water supply industry

Product characteristics:

TPEP anti-corrosion is the most advanced anti-corrosion both domestically and internationally, with a service life of over 50 years. The outer 3PE anti-corrosion coating is an introduction of Russian technology and has a history of nearly 70 years. The inner coating is a hot-melt epoxy powder coating, which is an introduction of Japanese technology and has also been in use for 50 years.

2. The inner wall is smooth, with a roughness of 0.0081-0.0091 (tested by the Testing Center of China Water Resources Research Institute), resulting in low head loss. When conveying the same flow rate of medium, the diameter can be reduced by one grade.

3. Strong adaptability to terrain. Steel pipes have strong flexibility.

4. Easy to install, safe and reliable. The length of a single pipe can reach 12 meters, and the number of connection ports is reduced by half.

5. The inner wall is smooth and free of scale, meeting food-grade requirements.

Inquiry