Contact Us

Mr.Yang:+86 15801686799

E-mail:yang@rssteelpipe.com

Add:Puwacheng Industrial Park, Yanshan Economic Development Zone

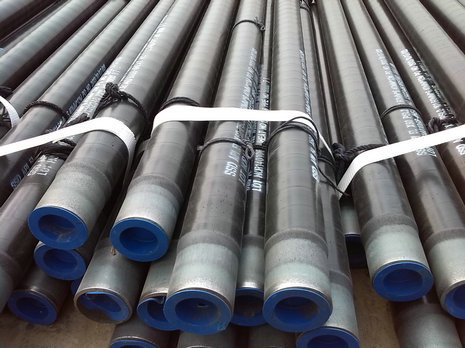

Lined with stainless steel composite steel pipe

The inner lining stainless steel composite steel pipe complies with the urban construction industry standard CJ/T192-2017. It is a thin-walled stainless steel pipe compounded on the inner wall of the steel pipe.

Key words:

Lined with stainless steel composite steel pipe

Classification:

Description

The inner lining stainless steel composite steel pipe complies with the urban construction industry standard CJ/T192-2017. It is a thin-walled stainless steel pipe compounded on the inner wall of the steel pipe. This bimetallic composite steel pipe significantly enhances the corrosion resistance of the steel pipe during water, hot water, gas, natural gas and oil transportation processes. The surface is smooth, with low fluid resistance, while retaining the high mechanical strength of the steel pipe. It can be connected by welding, grooves or threads, and has the advantages of good sealing performance. It overcomes the defects of galvanized steel pipes being prone to corrosion and plastic pipes connected by hot melt being prone to leakage and aging. It is an ideal product for upgrading and replacing gas, water and oil transmission steel pipes.

The inner lining of stainless steel composite steel pipes can be welded together. The welding process can refer to GB/T13148-1991 "Technical Conditions for Welding of Stainless Steel Composite Plates". It can also refer to Appendix A of JB/T4790-2000 "Welding Code for Steel Pressure Vessels". "Welding Regulations for Stainless Steel Composite Steel"

2. The bevel form can be in accordance with GB/T13148

Before welding, mechanical methods and organic solvents should be used to remove oil stains, rust, metal shavings, oxide films and other contaminants from the surface of the weld seam and within at least 20mm on each side of the welding groove.

4. The welding rods shall be A302(E309) as stipulated in GB/T983 "Stainless Steel Welding Rods", with a specification of Φ3.2.3.5

Manual arc welding is recommended. For welds with higher requirements, tungsten inert gas [ya] arc welding can be used as the base, and manual arc welding can be applied near carbon steel, or tungsten inert gas arc welding can be adopted throughout. When tungsten inert gas welding is adopted, the welding wire should be A302 with the same composition as E309.

Inquiry