Contact Us

Mr.Yang:+86 15801686799

E-mail:yang@rssteelpipe.com

Add:Puwacheng Industrial Park, Yanshan Economic Development Zone

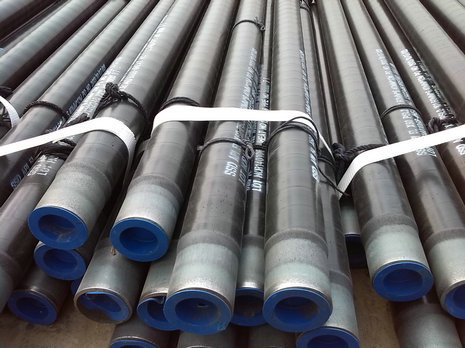

Wear-resistant pipe

A group industrial company specializing in the production of wear-resistant pipes, wear-resistant materials, and environmentally friendly and energy-saving series products.

Key words:

Wear-resistant pipe

Classification:

Description

A group industrial company specializing in the production of wear-resistant pipes, wear-resistant materials, and environmentally friendly and energy-saving series products. "Casting Alloy Series, Ceramic Composite Series, Polymer Series, Plastic-lined Anti-corrosion Series", National Electric Power Wear-resistant Pipe Research Institute, Wear-resistant Materials Testing Center.

The annual production capacity of casting alloy is 3,000 tons of alloy pipes, that of high molecular series is 2,000 tons of ultra-high molecular polyethylene pipes, that of ceramic composite series is 5,000 tons of ceramic composite steel pipes, and that of plastic-lined anti-corrosion series is 2,000 tons, achieving an annual output value of 200 million yuan.

The company is signing joint operation cooperation agreements with several major design institutes and installation companies that have national-level qualifications. The company has always adhered to the production scheduling based on drawings. It possesses the capabilities of pipeline engineering measurement, design, production and installation, as well as a complete after-sales service system.

The company's main products include high-tech new materials under the National "863 Program" such as SHS ceramic-lined composite steel pipes, ultra-high molecular weight polyethylene pipes, steel-lined polyurethane pipes, high-wear-resistant bimetallic pipes, rare earth alloy pipes, surfacing alloys, silicon carbide, turtle shell nets, hard ceramic veneers, ceramic armoring, plastic-lined pipes and pipe fittings: wear-resistant steel balls and wear-resistant liners.

The company's products are widely used in power powder conveying, ash transportation, desulfurization and flue ducts. Mine tailings conveying and washing system Coal washing system: Metallurgical high escort powder, dust removal, slag flushing, flue, nitrogen ash removal system: Ship dredging, sand pumping system; Systems such as ash conveying in cement plants, flue gas outlets of kilns and furnaces, silos, etc.

With scientific production techniques, strict quality management, advanced service concepts and reasonable product prices, the company has won a good reputation among a large number of users at home and abroad and is deeply trusted by customers at home and abroad.

Inquiry