Contact Us

Mr.Yang:+86 15801686799

E-mail:yang@rssteelpipe.com

Add:Puwacheng Industrial Park, Yanshan Economic Development Zone

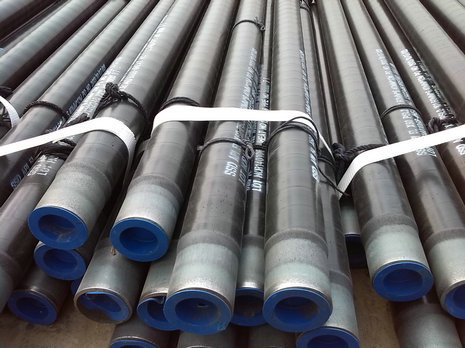

Oil Casing

Oil casings are mainly used in the drilling of oil and gas wells as well as the transportation of oil and gas. Specifically, they play a supporting role for the wellbore during the drilling process and after well completion, ensuring the smooth progress of the drilling process and the normal operation of the entire oil well after completion.

Key words:

Oil Casing

Classification:

Description

Oil casings are mainly used in the drilling of oil and gas wells as well as the transportation of oil and gas. Specifically, they play a supporting role for the wellbore during the drilling process and after well completion, ensuring the smooth progress of the drilling process and the normal operation of the entire oil well after completion. In addition, API oil casings must also have certain corrosion resistance to adapt to different downhole environments.

API oil casings are mainly used in the drilling of oil and gas wells and the transportation of oil and gas. These casings also need to have collapse resistance in areas with complex geological conditions.

API oil casings can be divided into different steel grades according to the strength of the steel itself, including J55, K55, N80, L80, C90, T95, P110, Q125, V150, etc. These casings of different steel grades are suitable for different downhole environments and pressure conditions.

27MnCrV is a new type of steel used in the production of TP110T grade oil casings. Compared with the traditional 29CrMo44 and 26CrMo4 steels, 27MnCrV contains less molybdenum (Mo) element, which can significantly reduce production costs.

To overcome the problem of high-temperature temper brittleness in 27MnCrV steel after normal austenitizing and quenching treatment, methods such as rapid cooling after tempering or intercritical quenching are usually adopted. Intercritical quenching involves heating in the α+γ two-phase region to retain some undissolved ferrite, thereby improving toughness while maintaining high strength, and reducing quenching stress and deformation.

For 27MnCrV steel pipes treated with intercritical quenching, the yield strength ranges from 820 to 860 MPa, the tensile strength ranges from 910 to 940 MPa, the impact toughness ranges from 65 to 85 J, and the collapse resistance qualification rate reaches 100%. This indicates that 27MnCrV steel pipes are a high-quality high-grade oil casing.

Inquiry